Polyethylene bags are transparent, waterproof containers used in various industrial, commercial, and home situations to preserve, store, or transport items. These poly bags are used regularly by the food, chemical, defense, waste management, retail, medical, construction, and a plethora of other industries. Although polypropylene bags are a popular and more affordable alternative to polyethylene bags, the latter has several advantages that make them more well-liked. Read More…

Diversified Plastics & Packaging supplies plastic bags for many industries. We deliver prompt service, competitive prices & unparalleled variety in flexible packaging. Fast quotes, free samples when needed, custom made poly bags and stock items of any color and size. Industrial, textile, medical, small & large flexible packaging markets. Visit our website today.

We’re NUTS about plastic bags! Buckeye Bag offers incredibly low prices on a wide selection of commercial quantity industrial plastic bags. Order securely from our online stock product catalog or request a fast, custom quote.

At Fantapak, we take pride in being a trusted manufacturer of high-quality plastic bags designed to meet the diverse needs of businesses across many industries. We have built our reputation on precision manufacturing, superior materials, and an unwavering commitment to customer satisfaction.

Miller Supply provides a complete line of poly bags, custom bags, boxes and other shipping supplies. Our product line consists of stock and custom boxes, tapes, poly bags, labels, foam plus other items such as packaging peanuts, bubble cushioning, stretch film, plastic and steel strapping, etc.

At LPS Industries, we take pride in being a trusted manufacturer and supplier of high-quality plastic bags and flexible packaging solutions that serve a wide range of industries. We have built our reputation on delivering dependable, innovative products designed to protect, preserve, and promote the goods our customers rely on every day.

Family-owned for over 75 years, we've been known for our outstanding customer service, a reputation we've earned by always treating customers the way we would like to be treated.

More Polyethylene Bag Manufacturers

Manufacturing Process of Polyethylene Bags

Polyethylene bags, sometimes referred to as poly bags or plastic bags, are among the most widely used flexible packaging solutions across multiple industries. Their popularity is due in large part to their durability, versatility, and cost-effectiveness. But how are polyethylene bags made? Understanding the manufacturing process can help buyers, procurement professionals, and manufacturers make informed decisions about which type of bag is most suitable for a given application.

The manufacturing journey begins with ethylene, a hydrocarbon derived as a byproduct from natural gas and petroleum refining. This ethylene is the foundational raw material for producing polyethylene plastic resins. Through a chemical process known as polymerization, a series of ethylene monomers are chemically bonded to create polyethylene polymers—the building blocks of poly bags. The resulting thermoplastic can belong to any of the numerous polyethylene subcategories, each with its own unique set of properties and use cases.

Distinctions between subcategories—such as high-density polyethylene (HDPE), low-density polyethylene (LDPE), and linear low-density polyethylene (LLDPE)—are determined by factors like molecular weight, degree of branching, and level of crystallization. For example, HDPE is known for its non-porous, rigid surface, making it ideal for applications requiring moisture and temperature resistance. By contrast, LDPE is more flexible and stretchable, offering superior clarity and resistance to tearing—qualities that make it preferred for retail and consumer packaging where product visibility is important.

In addition to HDPE and LDPE, there are several other grades and formulations of polyethylene, including the new generation metallocene polyethylene, medium density polyethylene (MDPE), ultrahigh molecular weight polyethylene (UHMWPE), and very low-density polyethylene (VLDPE). Each material offers specific benefits and trade-offs depending on the requirements of the end application—such as puncture resistance, flexibility, clarity, or chemical compatibility. For instance, UHMWPE is chosen for its extreme toughness and abrasion resistance, while LLDPE is valued for its balance of strength and flexibility, making it a staple in food packaging and industrial liners.

The manufacturing of polyethylene bags typically involves either the blown film extrusion or cast film extrusion process:

- Blown Film Extrusion: In this process, resin beads are heated to temperatures between 356 and 464 °F (180 and 240 °C). The molten polyethylene is forced through a circular die, forming a thin, continuous tube of film. Air is blown into the center of the tube, causing it to expand like a balloon. The resulting film is cooled, flattened, and wound into rolls.

- Cast Film Extrusion: Here, molten polyethylene is extruded through a flat die onto a chilled roller, creating a smooth, flat film. This method allows for greater clarity and uniform thickness.

After the film is produced and cooled, it is cut and sealed into the desired bag shape using heat sealing or other methods. Additional finishing steps—such as printing, adding reinforced handles, zipper closures, adhesive strips, or gussets—may be included based on customer specifications. Printing can be done using flexographic or rotogravure techniques to display branding, instructions, barcodes, or warning labels, further enhancing the functionality and marketing appeal of the bags.

Advantages of Polyethylene Bags

Polyethylene bags continue to dominate the packaging industry due to a wide range of benefits that support a variety of commercial, industrial, and consumer needs. Here are some of the key advantages that make poly bags an essential packaging material:

- Exceptional Durability and Flexibility: Polyethylene is exceedingly ductile and has excellent impact strength. Even with relatively low strength and hardness, it will stretch rather than break—minimizing the risk of tears or punctures during handling and transportation.

- Superior Moisture and Chemical Resistance: Polyethylene bags are highly resistant to water, many chemicals, and vapors, ensuring product protection in a range of challenging environments. This makes them ideal for packaging food, pharmaceuticals, chemicals, and sensitive electronics.

- Cost-Effective and Efficient: HDPE bags, in particular, represent one of the most affordable packaging options, offering high performance at a low price point. Their lightweight nature also reduces shipping costs and overall carbon footprint during distribution.

- Versatile Transparency: Depending on thickness and density, polyethylene ranges from nearly transparent (especially LDPE) to opaque, offering a choice between product visibility and privacy. This adaptability suits both retail display and secure storage needs.

- Good Electrical Insulation: Polyethylene is an excellent electrical insulator, making it suitable for packaging and protecting electronic components. While it can be prone to static buildup, anti-static additives or coatings can be incorporated for sensitive applications.

- Thermal Stability: Polyethylene’s melting points range from 221 to 239 °F (105 to 115 °C) for LDPE, and from 248 to 356 °F (120 to 180 °C) for medium and high-density grades. This broad thermal range enables use in both refrigeration and moderate heat environments.

- Recyclability: Polyethylene, particularly HDPE, is readily recyclable. Post-consumer poly bags are often reprocessed into products like composite lumber, piping, and new packaging materials, contributing to sustainability efforts when managed responsibly.

Want to know more about the benefits of polyethylene bags for your business?

Explore our buyer’s guide for detailed comparisons or jump to supplier selection tips further below.

Disadvantages of Polyethylene Bags

Despite their many advantages, polyethylene bags also pose several challenges and environmental concerns. Being aware of these limitations can help businesses make informed decisions or explore more sustainable packaging alternatives.

- Environmental Impact and Persistence: Polyethylene is not biodegradable and can take decades—or even centuries—to break down in landfills. This long decomposition period contributes to growing landfill volumes and environmental pollution.

- Emissions and Resource Depletion: The production of polyethylene is heavily reliant on finite fossil fuels such as petroleum and natural gas. The extraction, refinement, and manufacturing processes are energy-intensive and generate significant greenhouse gas emissions, notably carbon dioxide, which contributes to climate change.

- Challenges in Recycling: Although polyethylene is technically recyclable, the process of sorting, cleaning, and reprocessing different grades and types (HDPE, LDPE, LLDPE, etc.) is complex, costly, and not uniformly available across regions. Contamination with food, ink, or other plastics further complicates recycling efforts.

- Hazardous Incineration Byproducts: Incinerating polyethylene waste can release toxic compounds and hazardous gasses, presenting risks to air quality and human health. Safe disposal and advanced waste-to-energy technologies are required to mitigate these effects.

- Potential for Single-Use Waste: Many poly bags are designed for single-use, such as grocery sacks or packaging film, contributing to the global issue of plastic pollution in waterways, oceans, and urban environments.

Looking for eco-friendly alternatives to polyethylene bags?

Discover sustainable packaging solutions and learn more about compostable, biodegradable, and reusable bag options.

Applications of Polyethylene Bags

Polyethylene bags are utilized in an extensive range of industries and applications due to their customizable properties, cost-effectiveness, and durability. From industrial to retail and medical settings, here are some of the most common use cases and specialized types:

- Anti-Static Poly Bags: Poly anti-static bags are specifically engineered to reduce static electricity and guard against electrostatic discharge-related damage (ESD). These bags are essential for packaging and protecting electronic parts—such as circuit boards, semiconductors, and sensitive devices—that could be harmed by ambient static. Available in multiple thicknesses and sizes, anti-static poly bags often incorporate fire retardant materials and airtight seals for enhanced water protection.

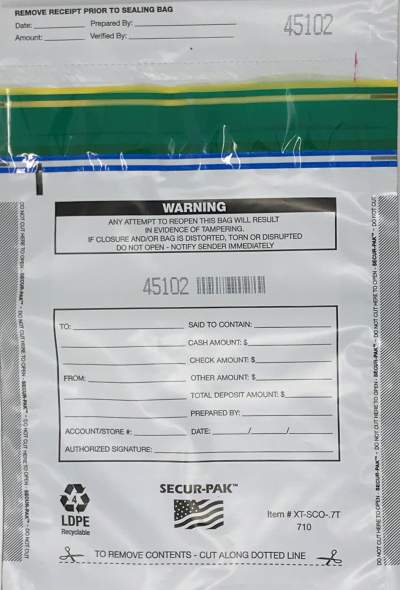

- Mailer and Shipping Bags: Mailing and shipping bags made from polyethylene are favored for e-commerce, logistics, and postal services due to their lightweight, tear-resistant construction. These mailer bags come in various closure styles—including zip closures, pressure closures, and peel-and-seal strips—and can be custom printed with branding, instructions, or barcodes. Poly mailers offer strong protection against moisture and contaminants during transit, making them a popular alternative to heavier corrugated boxes for non-fragile goods.

- Zipper Bags and Reclosable Bags: Zipper bags, also known as ziplock or reclosable poly bags, are prized for their secure closure, reusability, and strong solid edges. Available in a variety of sizes and thicknesses, they are widely used in both residential and commercial settings for freezer storage, bulk food packaging, parts organization, and sample containment. Industries such as pharmaceuticals, laboratories, and manufacturing rely on zipper bags for safe and reliable product preservation.

- Food Storage and Packaging: Polyethylene bags are FDA-approved for direct food contact, making them a primary choice for storing produce, baked goods, frozen foods, and snacks. Their moisture barrier properties and chemical inertness help maintain freshness and prevent contamination.

- Trash Bags and Liners: Heavy-duty polyethylene bags serve as garbage bags, can liners, and industrial waste sacks. Their puncture resistance and load-bearing capacity make them suitable for commercial and municipal waste management.

- Medical and Biohazard Bags: In hospitals, laboratories, and research facilities, colored or printed polyethylene bags are used to safely contain medical waste, specimens, and biohazardous materials.

- Retail and Merchandise Bags: Custom-printed HDPE or LDPE shopping bags are a staple in retail environments for carrying clothing, groceries, and consumer goods. Branding and marketing messages can be easily added through high-quality printing techniques.

- Industrial Packaging: Large-format poly bags, pallet covers, and shrink films protect machinery, building materials, and equipment from dust, moisture, and environmental damage during storage and transport.

How to choose the right polyethylene bag for your application?

Consider factors such as product weight, required clarity, barrier properties, closure type, size, and regulatory compliance. Contact our experts for personalized recommendations, or browse our catalog for common use cases.

Choosing the Right Polyethylene Bag Supplier

Selecting a reliable polyethylene bag supplier is crucial for ensuring product quality, regulatory compliance, and supply chain continuity. With so many manufacturers and distributors in the market, how can you identify the best partner for your organization’s unique requirements?

- Evaluate Supplier Capabilities: Use our directory of polyethylene bag suppliers to compare companies based on their experience, certifications (such as ISO 9001 or FDA compliance), production technologies, scalability, and customization abilities. Look for suppliers with in-house extrusion, printing, and converting capabilities.

- Request Product Samples and Certifications: Before committing to a large order, ask for product samples or technical data sheets to verify bag performance, thickness, and material quality. Ensure the supplier adheres to regulatory standards for food safety, environmental protection, and product traceability.

- Review Customer Support and Logistics: Reliable suppliers offer responsive customer service, consistent lead times, and flexible shipping options. Evaluate their ability to handle custom orders, rapid prototyping, and on-time delivery for high-volume or just-in-time manufacturing needs.

- Consider Sustainability Initiatives: More businesses are seeking suppliers with strong recycling, waste reduction, and green manufacturing practices. Ask about recycled content options, closed-loop recycling programs, and eco-friendly product lines.

Each polyethylene bag supplier in our directory has a comprehensive business profile page outlining their core competencies. Use the integrated contact form to directly request a quote, ask technical questions, or discuss your specific packaging challenges. You can quickly assess each business’s areas of expertise with our proprietary website previewer. For convenience, our streamlined RFQ form enables you to reach out to multiple polyethylene companies simultaneously—saving you valuable time during the sourcing process.

Ready to connect with trusted polyethylene bag suppliers?

Browse our supplier directory or request a quote now to compare prices and capabilities from top manufacturers.

Frequently Asked Questions About Polyethylene Bags

- What’s the difference between HDPE and LDPE bags?

HDPE (high-density polyethylene) bags are stiffer, stronger, and less transparent than LDPE (low-density polyethylene) bags, making them ideal for heavier items or those requiring moisture barriers. LDPE bags are softer, more flexible, and offer greater clarity, which is beneficial for retail display and food packaging. - Are polyethylene bags safe for food storage?

Yes, most polyethylene bags are FDA-approved for direct food contact. Always verify certifications and request documentation from your supplier to ensure compliance. - Can polyethylene bags be recycled?

HDPE and LDPE bags are recyclable in many regions, but local guidelines vary. Check with your municipality and look for drop-off locations or recycling services that accept plastic film. - How can I order custom-printed polyethylene bags?

Most suppliers offer custom printing options for branding, barcodes, warnings, or usage instructions. Contact suppliers with your artwork and specifications to receive a quote and digital proofs. - What are common thicknesses for polyethylene bags?

Polyethylene bags are available in a wide range of thicknesses, from lightweight 0.5 mil bags for produce to extra-heavy 6 mil bags for industrial parts. Choosing the right thickness depends on your application, product weight, and durability requirements. - How do I choose the best closure type?

Closure options include open-ended, zipper (ziplock), drawstring, adhesive seal, and heat-sealed. The best choice depends on factors such as reusability, tamper evidence, and ease of use.

Still have questions about polyethylene bag manufacturing, sourcing, or applications?

Ask our experts or visit our knowledge base for more in-depth information.

Summary: Why Polyethylene Bags Remain a Top Choice

Polyethylene bags continue to be the packaging solution of choice across industries—from food and retail to manufacturing and healthcare—thanks to their unmatched versatility, durability, and cost-effectiveness. Whether you need custom-printed merchandise bags, anti-static electronic packaging, or heavy-duty liners, poly bags deliver reliable performance with options tailored to your specific requirements.

As buyer awareness of environmental impacts grows, the industry is evolving to include more sustainable alternatives, enhanced recycling opportunities, and innovative materials. When sourcing polyethylene bags, prioritize suppliers with proven quality, customization capabilities, regulatory compliance, and a commitment to sustainability.

Ready to get started? Request a quote today contact us for expert guidance on choosing the best polyethylene bag solution for your business.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services