A poly bag is a widely used resource for shipping and packaging composed of polymer material. It is incredibly strong, flexible, and can be tailored to fit any use. Poly bags are a perfectly manufactured, compact technique for covering and securing goods, parts, and products. Read More…

Diversified Plastics & Packaging supplies plastic bags for many industries. We deliver prompt service, competitive prices & unparalleled variety in flexible packaging. Fast quotes, free samples when needed, custom made poly bags and stock items of any color and size. Industrial, textile, medical, small & large flexible packaging markets. Visit our website today.

We’re NUTS about plastic bags! Buckeye Bag offers incredibly low prices on a wide selection of commercial quantity industrial plastic bags. Order securely from our online stock product catalog or request a fast, custom quote.

At Fantapak, we take pride in being a trusted manufacturer of high-quality plastic bags designed to meet the diverse needs of businesses across many industries. We have built our reputation on precision manufacturing, superior materials, and an unwavering commitment to customer satisfaction.

Miller Supply provides a complete line of poly bags, custom bags, boxes and other shipping supplies. Our product line consists of stock and custom boxes, tapes, poly bags, labels, foam plus other items such as packaging peanuts, bubble cushioning, stretch film, plastic and steel strapping, etc.

At LPS Industries, we take pride in being a trusted manufacturer and supplier of high-quality plastic bags and flexible packaging solutions that serve a wide range of industries. We have built our reputation on delivering dependable, innovative products designed to protect, preserve, and promote the goods our customers rely on every day.

Family-owned for over 75 years, we've been known for our outstanding customer service, a reputation we've earned by always treating customers the way we would like to be treated.

More Poly Bag Manufacturers

Poly Bags: Manufacturing, Applications, Benefits, and Choosing a Supplier

Poly bags, also known as plastic bags or polyethylene bags, are indispensable packaging solutions used across a wide range of industries. These bags are crafted from high-quality polyethylene or polystyrene materials, providing versatile, cost-effective, and durable packaging options for commercial, industrial, and consumer applications. Although first developed during the industrial revolution, polyethylene became the primary material for poly bag production in the 1950s. Since then, the demand for reliable, secure, and practical methods of storing and transporting items has led to the widespread popularity of poly bags in global supply chains, retail, food service, healthcare, agriculture, and more.

What Are Poly Bags?

Poly bags refer to flexible packaging bags made from various types of plastic resins, most commonly polyethylene (PE) and polypropylene (PP). Available in a variety of sizes, thicknesses, and closure types, poly bags are engineered to meet the diverse requirements of packaging, shipping, and storage. They are lightweight yet strong, moisture-resistant, and capable of protecting contents from dust, dirt, and contaminants. Poly bags are available in clear, colored, or printed forms, with options like resealable zippers, adhesive seals, and custom printing for branding or labeling purposes. Common types of poly bags include flat poly bags, gusseted bags, resealable bags, anti-static bags, and custom-printed bags tailored to specific business needs.

How Poly Bags are Made: The Manufacturing Process

Understanding how poly bags are manufactured is essential for anyone seeking the highest quality packaging solutions. The strength, weight, and thickness of a poly bag are all influenced by the specific resin and manufacturing process used. Plastic bags are made from several types of resins, including:

- Low-Density Polyethylene (LDPE): Known for flexibility, clarity, and strength; ideal for light- to medium-duty packaging.

- Linear Low-Density Polyethylene (LLDPE): Offers additional tensile strength and puncture resistance; used for heavy-duty applications.

- High-Density Polyethylene (HDPE): Provides excellent stiffness and chemical resistance; used in grocery bags, food packaging, and more.

- Medium-Density Polyethylene (MDPE): Balances flexibility and density; often used in retail and industrial packaging.

- Polypropylene (PP): Offers high clarity and heat resistance; preferred for food-grade bags and specialty applications.

The main determinants of a bag's durability and strength are its composition and physical attributes. Therefore, choosing the appropriate bag material is the first step in designing and producing high-quality, cost-effective poly bags for your application. Are you wondering which poly bag material is best for your business? Explore our guide on choosing between LDPE, HDPE, and PP bags for specialized uses.

Step-by-Step Poly Bag Manufacturing

After selecting the resin, it is introduced into the hopper of an industrial extruder. Historically, plastic pellets were melted by heating them in a tank or barrel, which often led to uneven melting. Modern manufacturing has evolved with the invention of the extruder: a screw mechanism that efficiently and evenly heats plastics at temperatures between 350 to 450° F (176.6 to 232.2 °C). This ensures uniform melting of the pellets, resulting in consistently high-quality poly bags.

The extruder consists of a loading hopper at one end and a die at the other. As the screw rotates, resin pellets are fed into the barrel and gradually heated by external heating units. The molten plastic resin is then forced through the extruder die, emerging as a continuous tube or “bubble.” This tube is stretched and expanded to the desired width and thickness, forming the initial structure of the poly bag.

The plastic tube is maintained inside a tall cooling tower, where it resembles a vertical balloon. As it rises, the gas expands the tube, which cools as it ascends and comes into contact with the tower’s walls. Once cooled, the tube travels to the cutting rollers, where it is prepared for further processing.

Next, the tube passes through a collapsing frame, shaping it into flat plastic fabric. Nip rollers flatten the tube into a lay-flat state, ready to be wound into large rolls. These rolls allow for greater efficiency in downstream operations such as printing, measuring, cutting, and sealing. Nip rollers also provide web tension control and improve traction for continuous processing.

The flattened film is wound onto giant rolls, from which poly bags are cut and manufactured according to customer specifications. Printing, custom sizing, sealing, and handle formation are performed at this stage. Some bags are also equipped with gussets—folded sides or bottoms that expand to provide additional capacity. The manufacturing process is highly customizable, ensuring that each poly bag is tailored to its intended application, whether for retail, food service, medical, or industrial use.

Key Benefits of Poly Bags

Why choose poly bags over alternative packaging materials such as paper, woven sacks, or biodegradable options? Consider the following advantages:

- Cost-Effectiveness: Poly bags are less expensive to produce and transport due to their lightweight nature, reducing shipping costs and environmental impact.

- Versatility: Available in a range of sizes, thicknesses, and shapes, poly bags can be tailored to package virtually any product, from small parts to large textiles.

- Durability and Strength: High resistance to punctures, tears, and moisture makes poly bags ideal for protecting goods in transit and storage.

- Barrier Properties: Many poly bags offer excellent protection against moisture, dust, UV light, and chemicals, preserving product freshness and integrity.

- Printability: Poly bags can be custom printed with branding, product information, barcodes, and instructions to enhance the customer experience and support marketing goals.

- Recyclability: Many poly bags are recyclable, supporting sustainable packaging initiatives and reducing landfill waste when disposed of properly.

- Compliance: Food-grade poly bags meet FDA and USDA requirements, ensuring safe storage and transportation of consumable goods.

Want to discover how poly bags can boost your business's efficiency and sustainability? Read our in-depth article on the environmental impact and recycling options for poly bags.

Applications of Poly Bags: Industry Use Cases

Poly bags are utilized across numerous industries and applications. Their adaptability makes them a preferred choice for businesses seeking reliable, high-performance packaging solutions. Below are some of the most common uses:

- Food Packaging Bags: Poly food bags maintain freshness and protect against moisture, air, and contaminants. Options include vacuum-sealable bags that extend shelf life by removing air, and clear bags for produce display. To be designated as food service or storage bags, poly bags must comply with FDA and USDA standards. Look for certification stamps on compliant products. Poly bags for food packaging are available in zip-lock, flat, and gusseted designs for items such as baked goods, snacks, meats, produce, and more.

- Trash Bags and Liners: Poly garbage bags—ranging from small office liners to heavy-duty yard waste bags—are a staple in both commercial and residential waste management. Features like drawstrings, handles, and odor control have revolutionized the trash collection industry. Many waste management companies require the use of sturdy poly trash bags for non-recyclable waste to ensure hygienic handling and transport.

- Retail and Shopping Bags: Poly bags are ubiquitous in retail as take-home bags, merchandise bags, and checkout bags. Their strength, custom printability, and cost-effectiveness make them ideal for retailers seeking to reinforce their brand while providing a convenient customer experience.

- Industrial Packaging: Heavy-duty poly bags protect bulk materials, hardware, parts, and components from moisture, corrosion, and contamination. Anti-static and UV-resistant options are available for sensitive electronics and outdoor storage.

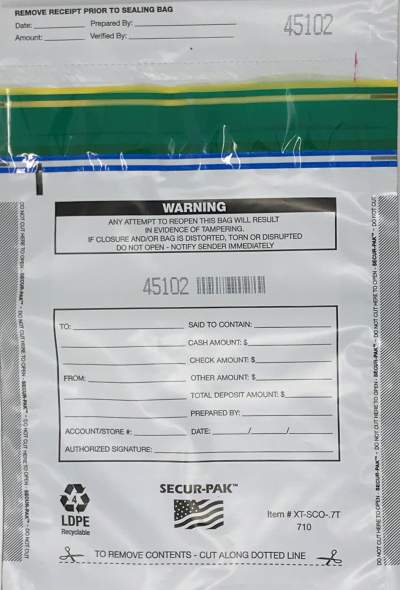

- Medical and Pharmaceutical Bags: Poly bags are critical in healthcare for sterile packaging, specimen transport, and pharmaceutical storage. Medical-grade poly bags offer tamper-evidence, labeling, and compliance with regulatory standards.

- Mailing and Courier Bags: Tamper-evident poly mailers and courier bags provide secure, lightweight solutions for e-commerce shipping and parcel delivery, protecting contents from weather and unauthorized access.

- Specialty Bags: Custom poly bags are engineered for specific needs such as garment bags, mattress bags, sandbags, and anti-static bags for electronics.

How to Choose the Proper Poly Bag Manufacturer

Choosing the right poly bag manufacturer is a critical decision that impacts your packaging quality, compliance, lead time, and total cost of ownership. Here are key decision factors and actionable steps for buyers:

- Material Quality and Compliance: Ensure the manufacturer uses certified resins and complies with industry standards such as FDA, USDA, or ISO certifications for food and medical use.

- Customization Capabilities: Look for suppliers offering custom sizes, thicknesses, printed designs, and specialty features such as resealable closures, gussets, or anti-static properties.

- Production Capacity and Lead Times: Assess whether the manufacturer can meet your volume requirements and deliver within your desired timeframes. Inquire about minimum order quantities and turnaround times.

- Sustainability Initiatives: Consider manufacturers that offer recycled content, biodegradable options, or take-back programs to support your sustainability goals.

- Price Competitiveness: Request detailed quotes and compare pricing, factoring in value-added services such as design support, logistics, and customer service.

- Reputation and Experience: Review the manufacturer’s track record, industry reputation, and years of experience in producing poly bags for your sector.

To ensure the best outcome when purchasing poly bags from a poly bag manufacturer, compare several companies using our comprehensive directory of poly bag manufacturers. Each manufacturer profile highlights areas of expertise, capabilities, compliance certifications, and a convenient contact form for requesting quotes or additional information. Our proprietary website previewer allows you to quickly evaluate each company’s specialties and product offerings. Ready to get started? Use our simple RFQ form to contact multiple poly bag companies with a single submission and streamline your supplier search.

Frequently Asked Questions About Poly Bags

- What is the difference between LDPE, HDPE, and PP bags? LDPE bags are flexible and clear, HDPE bags are stiffer with better chemical resistance, and PP bags offer high clarity and are heat-resistant—making them suitable for different packaging needs.

- Can poly bags be recycled? Yes, most poly bags are recyclable. Check with your local recycling provider for accepted materials and proper preparation guidelines.

- Are poly bags safe for food contact? Food-grade poly bags are manufactured under strict guidelines to ensure safety for direct food contact. Look for FDA and USDA compliance markings.

- How can I order custom poly bags? Contact a reputable poly bag manufacturer or supplier. Most offer custom sizing, printing, and feature options to match your requirements. Use our directory to request quotes and samples.

- What are the minimum order quantities for custom bags? Minimum order quantities (MOQs) vary by manufacturer and bag type. Some suppliers accommodate small runs, while others specialize in bulk production.

Poly Bags and Sustainability: Are Plastic Bags Eco-Friendly?

Sustainability is a growing concern for businesses and consumers alike. Poly bags, when manufactured responsibly and recycled properly, can be part of a sustainable packaging strategy. Many manufacturers now offer bags made from recycled content or biodegradable resins. Polyethylene and polypropylene bags are often accepted at designated recycling centers, helping reduce landfill waste. Advances in manufacturing have also led to thinner, stronger bags that use less material while maintaining performance.

Interested in greener packaging solutions? Learn about eco-friendly poly bag alternatives, biodegradable plastics, and how to implement sustainable practices in your packaging operations.

Where to Buy Poly Bags: Supplier Comparison and Buying Tips

Are you searching for reliable poly bag suppliers or manufacturers? Our poly bag manufacturers directory provides a curated list of industry-leading suppliers offering competitive pricing, custom solutions, and nationwide or international shipping. When evaluating suppliers, consider the following:

- Request product samples to assess quality and fit for your application.

- Verify compliance with food safety or industry regulations.

- Ask about customization options and order flexibility.

- Compare pricing, lead times, and value-added services.

- Check for positive customer reviews and testimonials.

Ready to make an informed purchase? Contact multiple suppliers through our RFQ tool and receive competitive quotes tailored to your needs.

Summary: Why Poly Bags Remain a Top Choice for Packaging

Poly bags continue to set the industry standard for flexible packaging thanks to their durability, versatility, cost-effectiveness, and adaptability to custom specifications. Whether you need food-grade bags, industrial liners, retail shopping bags, or custom-printed packaging, poly bags deliver reliable performance across countless applications. By partnering with reputable manufacturers and embracing sustainable practices, businesses can ensure their packaging solutions meet both operational and environmental goals.

Have more questions or need expert guidance on selecting the right poly bag for your application? Explore our resources, contact a specialist, or request a quote to start your packaging journey today!

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services